Rewinding fire hydrant hoses. The State Fire Inspectorate Inspector Requires Hose Rewinding to be Rewinded by a Third-Party Licensed Organization. Is This Demand Legal? Why do you rewind fire hoses?

The water supply hose for extinguishing a fire is the most important working part of special equipment. Regular re-rolling of fire hoses is required to monitor their integrity. If there are cracks, tears, or punctures in the rink, uninterrupted water supply will become impossible; fire element will not be defeated.

This is why all fire departments strictly adhere to fire hose re-rolling schedules, even if the equipment is stored in perfect conditions.

The length of the hose should be carefully considered before purchasing. For hose attacks, the most common ones are 50 and 100 feet. Two 50" lengths will always cost a little more as there are additional set couplings required compared to one 100-in. Proponents of 100-inch lengths often cite economic efficiency, as well as the lack of additional communication, which can cause problems with obstacles when driving around corners.

What is the product? Sleeve structure

Supplying the hose is a completely different story. When using 3" hose, it is typical to see a length of 50" as this line is also regularly used with leader lines. The 50-inch length makes stretching, breaking and operating lines easier for the members who are required to perform it. A larger diameter feed line is often best specified at a 100-inch length, since the lack of additional couplings can provide a noticeable increase in overall bandwidth hose in the hose cable.

Instructions and rules for rolling fire hoses

- REGULARITY. In the Rules fire safety(PPB RF 01-03, paragraphs 89, 91) rolling of fire hoses is a mandatory procedure that is recommended to be performed at least once every 6 months (six months).

The check includes:

- hose rewinding;

- hydraulic test.

- MARKING. Registration regulations provide for marking on rolls. When rolling fire hoses, the integrity of the markings must be checked and a new one must be applied if necessary. After completing the task, the sleeve must be wound up again for further storage.

- SPECIAL CONDITIONS. Flexible water pressure hose can be used as part of emergency outdoor piping systems. In such areas, rewinding is carried out more often than in interior fire extinguishing systems.

It should be taken into account that in conditions severe frosts The fabric base of the hose may become frozen - it is necessary to defrost, wash, and dry.

The best way to eliminate the rip of these longer than 100 inches when they are too long is to have at least one 50-inch and one 25-inch "bottom" section of supply hose. Ideally, carrying two of them provides greater flexibility, especially when your propulsion companies are connecting to four-way valves or connecting multiple power lines to the rig.

Volumetric calculation can be used to determine the amount of fire hose that will fit in a given space. This calculation works in terms of volume, but you must consider the flat width of the hose when determining the size of the beds, how many dividers to install, and how far apart their spaces are. For the department switching brands or hose diameters, always make sure to measure the hoses or manholes before purchasing so you don't have to make installation adjustments after the fact.

Algorithm for rolling fire hoses

Rewinding of fire hoses is carried out by qualified fire department employees using special equipment.

Procedure:

- flushing- water is supplied to the hose under pressure, breakthroughs are detected;

- drying- the sleeve is placed in a special shaft, where it is evenly dried;

- renovation work- if holes/cracks/breaks are detected, they are eliminated using one of the suitable methods (vulcanization, hot bonding);

- rewind- produced with a hose offset of 90⁰.

Obtain the flat hose width and bowl coupling diameter from the hose manufacturer. For example, a 2" hose with 2 ½" couplings has couplings that end up wider than the hoses when flat, causing storage issues in the hoses if not taken into account.

Yours best resources when specifying and purchasing hose are your local fire equipment suppliers. They often have sample samples for evaluation, including "cut" samples that show hose design and materials. You can even get a full-size hose to test the fit and see how easy it is to work with. Feel free to contact the manufacturer directly. Many companies will meet with you, remove a demo hose, and help you evaluate it. Just make sure you compare brands during this process and ask representatives for more information.

IMPORTANT! Rolling must not be done manually, only with special equipment.

There are several types of water hose roll:

- single;

- double;

- harmonic;

- eight.

Each of the methods has its own area of application: single roll - for warehouse storage, figure eight and accordion - for various machines and extinguishing circumstances. Only a fire service specialist has the right to determine which rewinding technique to use in a particular case.

Benefits of working with us

Sometimes the sales or specifications are missing specific information that helps you compare a product to another brand. Find out if the manufacturer tests each hose length assembled and what pressure it is. Ask them if they are willing to provide evidence of this testing. Some manufacturers fail to test the hose after using couplings. Also be careful with fire extinguishing hoses or trade deals. They can purchase imported hose or purchase it from other suppliers and rebrand it.

If the rolling of fire hoses is carried out with violations of technology, the quality of the equipment may deteriorate. Hose defects that are not detected in time lead to a decrease in the effectiveness of fire fighting or make fire extinguishing impossible. The risk of severe consequences of an emergency in such cases increases greatly.

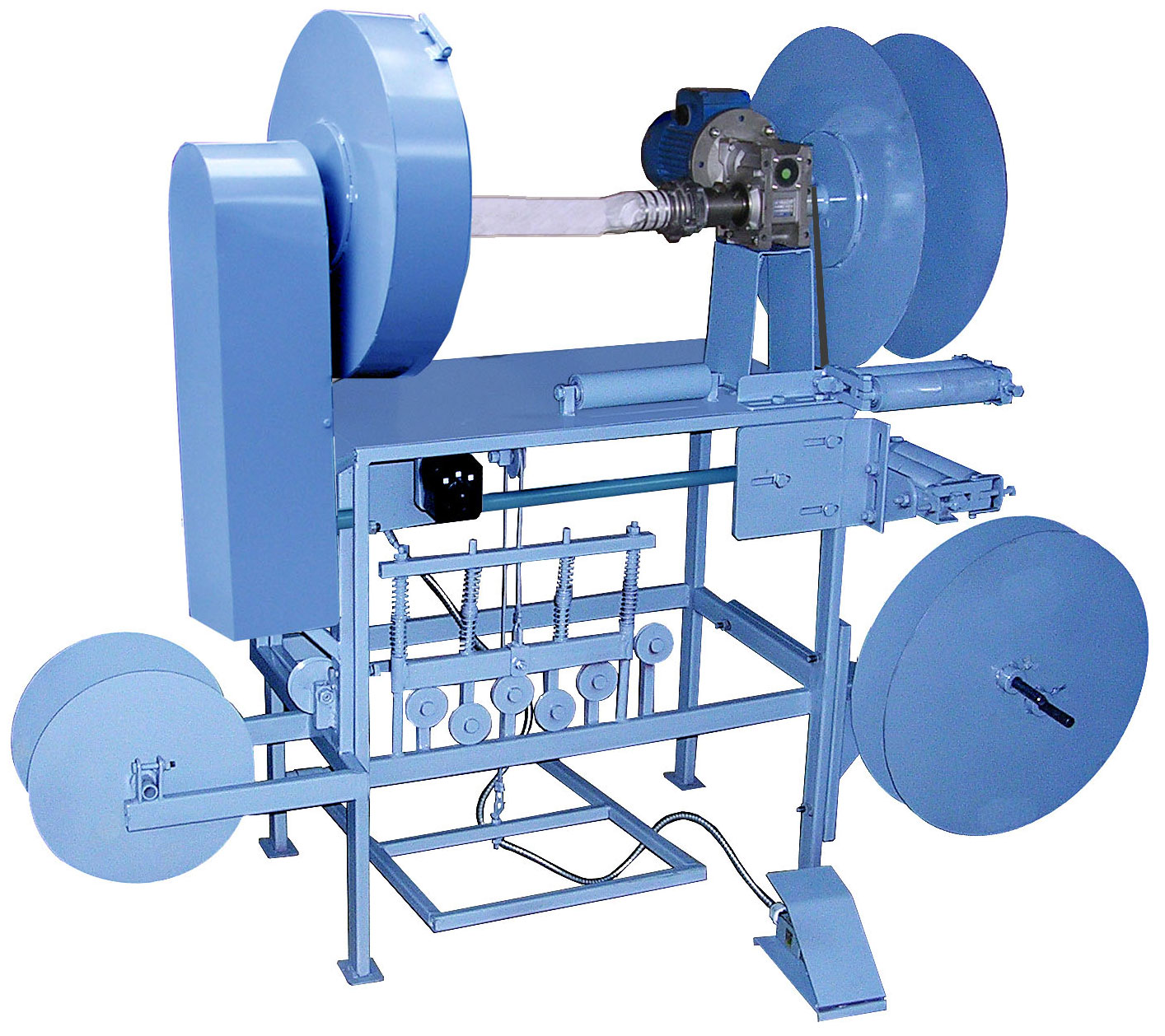

The operation of the fire extinguishing system directly depends on the coordinated activities of each participant in the work process and the quality of the equipment used. A fire hose rewinding machine ensures that the hoses are ready for immediate use in the event of an emergency.

Ask about the company's history, material origins and production location and processes. Be familiar with your local requirements and laws when we're talking about about the purchase. If you are tasked with soliciting three quotes, for example, try to find three vendors who sell the same brand of hose so you can't compare quotes from different manufacturers or have dirty hoses on your machines. ask for shipping costs separately so they don't contaminate the actual hose prices.

Don't forget to compare warranties and small font, you want to know what's covered and what's not. With warranties, be sure to check the terms of the “comprehensive” warranties, which cover all types of damage, delamination warranties, and workmanship warranties.

Considering the need for quick work in case of emergencies, specialized equipment for extinguishing fires, such as a machine for rewinding fire hoses, a drawing of which can be found on the Internet if necessary, should be present in every specialized service.

Why do you need a single roll?

Finally, come up with a replacement plan. Despite annual testing, it is still difficult to determine the effects of time and wear on the hose. Your plan should consider the warranty, frequency of use, storage conditions, and performance characteristics during testing. This strategy will impact firefighter safety and provide ease of budgeting.

Remember: there is no “one size fits all” fire hose. It's important to do homework, be aware and ask questions of your sales representative and manufacturers. This will help you achieve your department's provisioning goal. best quality By best price for best hose life.

It is worth noting that today you can also purchase ready-made versions of this product, produced in industrial conditions. The range includes a choice of manual and automatic models. An alternative option is to independently manufacture such a product for rewinding fire hoses.

It will also successfully meet the needs of rewinding fire hoses into a new roller during fire training and field trips. emergencies. Such equipment simplifies the process of operating this type of specialized equipment for demolition. Including its drying and washing, it facilitates regular maintenance.

Types of fire hoses

Review these standards to better understand the products. Below are some of the changes found in new edition. Type 3 - with double cover, designed for naval and industrial areas; Type 4 and 5 - industrial area, oil areas requiring greater abrasion resistance and fire service. In other states of the Federation there is slight variation in the length of each hose and this standardization is at the discretion of the respective state fire departments.

The inner tube made of synthetic rubber should have perfect finishing with nylon fabric, smooth tube and uniform thickness of its tube as its main characteristics. Outer fabric - made of synthetic fibers. These fibers must have good resistance to chemicals, good abrasion resistance, high tensile strength and should not contain mold when stored in a humid environment. The outer fabric consists of two main parts: warp and weft nylon threads.

The procedure for using fire equipment is strictly regulated by GOST and technical regulations; violation of storage principles leads to possible fines from regulatory authorities. Self-made machines for rewinding fire hoses are often not ready to provide storage at the proper level.

Reasons for the need to use re-rolls for fire hoses.

The weft is a set of wires that run in a circle around the inner tube. During their manufacture, in circular weaving, these two threads are intertwined. Its function is to protect the hose from circular pressure. Vulcanization is the process by which a rubber tube is inserted into a nylon cap. The ends of the hoses are connected to a tube into which water vapor is injected, establishing a connection between the inner tube and the outer fabric. The rubber tube undergoes a curing process through which it can subsequently be used. rubber tube changes depending on the operating pressure to which the hose will be exposed.

- Storing a fire hose without rolling it causes creases and cracks to appear.

- There is no danger of the sleeve sticking.

- Water will be freely supplied to the fire extinguishing site.

- Allows you to eliminate the risk of fines being imposed by state authorities.

Features and design of the machine

A high-quality device makes rolling up sleeves several times faster. The sleeves do not roll up and do not deteriorate during storage. The finished device can be compactly placed on the rear wall of the car.

This device includes:

- Bracket with a built-in folding stand;

- Specialized clamp;

- Disc and removable handle;

- Firehose;

- Rigid type fastening.

The finished device is a permanently fixed fixture. It is permanently mounted on a column. The device is based on a tubular metal axis. It rotates on bushings also made of metal. Corners are welded to the bushings, in which fasteners are created for fixation.

To use this device, the work of two firefighters is enough.

The advantage of using such a rolling device is the ability to collect literally all the necessary parts on a nearby scrap metal pile. In the absence of a factory-made device, such equipment can be used successfully and for a long time.

The advantage of using such a rolling device is the ability to collect literally all the necessary parts on a nearby scrap metal pile. In the absence of a factory-made device, such equipment can be used successfully and for a long time.

An easy-to-use machine for rewinding fire hoses onto a new roller significantly extends the life of such equipment. Hoses with a diameter of 51, 66 and 77 meters can be used. Rolling is possible on both single and double edges. Single and double rolling is produced.

When choosing equipment for rolling up a fire hose, it is important to give preference to models made in industrial conditions.

Factory-built equipment options can be adjusted to suit the height of the operator doing the rolling. Factory models are necessarily equipped with special stops that stop the hose winding.

A machine for rewinding fire hoses onto a new rib is offered for sale. In such a situation, the device works only by rolling once.

Such equipment also makes it possible to easily and constantly carry out the mandatory maintenance of hoses necessary for fire extinguishing. It is necessary to carry out such work because the slightest violations the integrity of these devices becomes the basis for the imposition of penalties by fire control services.

How to make a machine for rewinding fire hoses with your own hands

In the absence of specialized equipment made in an industrial environment, such a machine is quite easy to make independently. Such a device is primarily a roller on which the sleeve is wound. It’s enough just to see how the “Device for rolling and rolling fire hoses PSR-1” looks to easily make a similar model yourself.

To make such a product, you only need to select a disk onto which the sleeve will be screwed. For ease of use, a locking handle is attached to the disc. It will help you rewind the sleeve to the desired length and, if necessary, fix the rewind level.

To make such a product, you only need to select a disk onto which the sleeve will be screwed. For ease of use, a locking handle is attached to the disc. It will help you rewind the sleeve to the desired length and, if necessary, fix the rewind level.

You can mount such a device on a tripod or use the back wall of a fire truck to fix it. Moreover, today such equipment is on sale in large quantities. Among the offers you can choose from fully automatic or fully manual devices. Convenient, compact options with electric drive.

Several models from manufacturers

Models of such equipment include:

- TC-11P, based on performing work only in manual mode.

- TC-11, used for rolling up fire hoses manually.

- TC-52, used for rolling hoses using an electric drive.

The use of automated fire-fighting devices for rolling up fire hoses greatly speeds up the process of performing such activities. By increasing the speed, the product can begin to be used to its maximum short term. Such efficiency is extremely important when dealing with emergencies.