Study of the process of thermal decomposition of scorodite and pyrite. Change in the volume of the solid phase of pyrite oxidation products Healing properties of the mineral

1The work presents the results of thermal analysis of samples of monofractions of scorodite (FeAsO4) and pyrite (FeS2), as well as their mixture in a ratio of 3:1. It has been established that the thermal decomposition of scorodite occurs in three stages, and the temperature ranges and thermal effects of these reactions have been determined. The results of the thermal decomposition of pyrite showed that pyrite decomposes in two stages to pyrrhotite and a small amount of magnetite. It has been experimentally proven that a mixture of scorodite and pyrite decomposes in two main stages; according to X-ray phase analysis, the final decomposition products are pyrrhotite and magnetite. Based on the results of this study, recommendations will be developed for optimizing the process of roasting gold-bearing scorodite ore with pyrite concentrate in an atmosphere of superheated water vapor.

thermal analysis

speeds up

superheated steam

1. Markosyan S.M., Markosyan S.M., Antsiferova S.A., Timoshenko L.I. Method of differential thermal analysis in assessing the efficiency of beneficiation of sulfide ores // Modern problems of science and education. – 2014. – No. 3. URL: http://science-education.ru/ru/article/view id=13389.

2. Paleev P.L., Gulyashinov P.A., Gulyashinov A.N. Thermodynamic Modeling of Dearsenation of Rebellious Gold–Quartz–Arsenic Ore in Water Vapor // Journal of Mining Science. – 2016. – Vol. 52. – No. 2. – P. 373–377.

3. Gulyashinov P.A., Paleev P.L., Gulyashinov A.N. Study of the roasting process of gold-containing scorodite ore // Bulletin of ISTU. – 2016. – T. 20, No. 10. – P. 154–162.

4. Gzogyan S.R., Chanturia E.L. The influence of thermal effects on iron sulfides and oxides // Mining Information and Analytical Bulletin. – 2010. – No. 5. – P. 63–69.

5. Chepushtanova T.A. Physico-chemical properties and technological basis for obtaining pyrrhotines from pyrite: dis. ...cand. tech. Sci. – Alma-Ata, 2009. – 143 p.

At present, rich and easy-to-process deposits of precious and non-ferrous metal ores have been practically worked out; the basis of the modern mineral resource base of the Russian Federation mainly consists of difficult-to-process poor, finely disseminated and difficult-to-process ores. These ores include gold-arsenic ores, this is due to the close association of gold with arsenic-containing minerals. Such gold is called invisible because it cannot be detected by optical methods. Refractory ores require preliminary processing to achieve an acceptable level of gold recovery during their subsequent cyanidation. All pre-treatment methods involve breaking down the mineral matrix to release the gold.

Thermal analysis (calorimetry) is a method for studying physical and chemical processes based on recording thermal effects accompanying the transformation of substances under temperature programming conditions. This method is widely used not only in analytical chemistry, but also in geology for the identification of various minerals and rocks. It should also be noted that thermal analysis is convenient for laboratory research, does not require a large volume of starting material, and can be used as an express method for studying mineral raw materials. This method may be especially useful for refractory gold-containing raw materials (including sulfide), due to the high labor intensity and complexity of assay analysis.

To confirm the previously obtained results of thermodynamic modeling and calculation of the kinetic parameters of scorodite firing, studies were carried out on the thermal decomposition of scorodite and pyrite (monofraction), as well as a mixture of scorodite and pyrite in a ratio of 3:1.

Materials and research methods

The objects of the study were: gold-bearing oxidized scorodite ore of the Kozlovskoye deposit (Kalgan region, Transbaikal region). According to mineralogical analysis, the ore contains: quartz - 54%, scorodite - 35%, feldspars and aluminosilicate rocks - 11%. In the ore sample under study, the valuable components are gold (16.9 g/t) and silver (52.5 g/t). As well as substandard pyrite concentrate from the former tungsten-molybdenum plant (Zakamensk, Republic of Buryatia). According to chemical analysis, the pyrite concentrate contains, %: Stotal - 38.3, Fe - 35.8, SiO2 - 24.2, Pb - 0.81, Zn - 0.78. Pyrite concentrate can be used as a sulfidizer when roasted in an atmosphere of superheated water vapor.

Thermal analysis was carried out by differential thermogravimetry (DTG) and differential scanning calorimetry (DSC) using a Netzsch STA 449 F1 Jupiter simultaneous thermal analysis device.

Thermograms were recorded in platinum crucibles under the following conditions: atmosphere - argon, temperature range 20-1000 °C, heating mode - linear, sample heating rate 10 °C/min, sample weight 15-20 mg. During the heating process, changes in the mass of the mineral sample under study (TG curve), the rate of mass change (DSC curve), temperature (T), as well as the thermal effects of the reactions (J/g) were recorded.

Research results and discussion

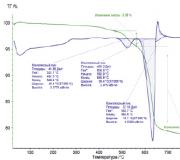

The analysis data presented in Fig. 1 indicate that the decomposition of scorodite occurs in 3 stages. The DSC and TG curves show that in the temperature range 162-215 °C there is a loss of mass (up to 5.35%), with the absorption of a significant amount of heat (-205.3 J/g). What explains the loss of water from scorodite:

FeAsO4. 2H2O → FeAsO 4 + 2H 2 O. (1)

At a temperature of 466-488 °C, with a significant loss of mass (19.25%), the decomposition process of anhydrous scorodite occurs according to the formula

2FeAsO 4 → Fe 2 O3 + As 2 O5. (2)

When the sample is heated above 550 °C, an exothermic peak (7.15 J/g) is observed, which indicates the decomposition of As 2 O5:

As 2 O5 → As 2 O3 + O2. (3)

According to XRF data, the final product of scorodite decomposition is magnetite (Fe3O4).

The thermal decomposition of pyrite is well described by a number of authors. Thermogram shown in Fig. 2, obtained on a sample of the pyrite monofraction, shows that the decomposition of pyrite also occurs in 3 stages. In the temperature range of 491-549 °C, thermal dissociation of pyrite occurs with the formation of elemental sulfur with a slight loss of mass with an endothermic effect (-41.89 J/g):

2FeS 2 → 2FeS + S 2 . (4)

With a further increase in temperature, a significant endothermic peak is observed with the greatest mass loss (16.19%), this is explained by the further decomposition of pyrite according to the overall reaction:

4FeS 2 + 11O 2 → 2Fe 2 O3 + 8SO 2. (5)

Rice. 1. Thermogram of scorodite decomposition

Rice. 2. Thermogram of pyrite decomposition

Rice. 3. Thermogram of decomposition of a mixture of scorodite and pyrite

Rice. 4. Diagram of a laboratory installation for firing in an atmosphere of superheated water vapor: 1 - heater; 2 - vessel with distilled water; 3 - reactor; 4 - oven; 5 - boat with ore; 6 - control solution; 7 - control solution cooling tank

Due to the lack of oxygen, the following reaction is likely to occur:

3FeS 2 + 8O 2 → Fe 3 O 4 + 6SO 2. (6)

The final product of pyrite decomposition is pyrrhotite (FeS), as well as a small amount of magnetite (Fe 3 O 4).

Of greatest interest is the thermogram of the decomposition of a mixture of scorodite and pyrite 3:1 (Fig. 3), in this proportion the mixture will be supplied to sulfidizing roasting. When the temperature range of 153-197 °C is reached, some mass loss occurs (2.74%), with the absorption of a significant amount of heat. The resulting endothermic peak indicates water loss from the scorodite.

The TG and DSC curves show that the maximum weight loss (up to 13.4% in total) occurs at a temperature of 450-590 °C, there is also a maximum endothermic peak (-129.5 J/g), it is most likely that in this range temperatures, decomposition of scorodite and pyrite occurs, as well as sulfidation of the released arsenic oxide with elemental sulfur. The end products of the reactions are magnetite (Fe3O4) and pyrrhotite (FeS). All arsenic is released into the gas phase.

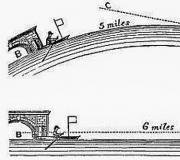

To confirm the results of thermal analysis, experimental laboratory studies were carried out to determine the final products of roasting in an atmosphere of superheated water scorodite ore and pyrite concentrate in a “flow-through” laboratory installation (Fig. 4).

This laboratory installation consists of four main components - an electric furnace, a heater, a reactor and a vessel with a gas absorber. The temperature in the reactor is measured by thermocouples of the XA type and is regulated by a microprocessor electronic thermostat MPRT-22, which was installed to automate the firing process. When the required firing temperature was reached, superheated water steam was supplied to the reactor, then an alundum boat was loaded with a portion of scorodite ore and pyrite concentrate weighing from 2 to 3 g. The beginning of the firing process was considered to be the moment when the portion of the charge was introduced. Firing temperature 700 °C, firing duration 25 minutes. The resulting cinders were subjected to X-ray phase analysis.

In Fig. Figure 5 shows an X-ray diffraction pattern of the obtained cinders; it was found that after firing the final iron-containing phases are magnetite (Fe 3 O 4) and pyrrhotite (FeS).

Thus, based on the studies conducted, the temperature ranges during the decomposition of the studied minerals, as well as the predominance of endothermic effects, were established. It has been experimentally confirmed that when firing a mixture of scorodite ore and pyrite concentrate in a ratio of 3:1 (firing temperature 700 °C, firing duration 25 minutes), in an atmosphere of superheated water vapor, the final products are magnetite (Fe 3 O 4) and pyrrhotite (FeS) .

Rice. 5. X-ray of the cinder

Research has been carried out on the thermal decomposition of scorodite and pyrite monofractions in an argon atmosphere. The temperature ranges and thermal effects during the decomposition of monofractions of scorodite, pyrite and their mixture in a 3:1 ratio were determined. The predominance of endothermic effects during the decomposition of the studied minerals in an inert atmosphere is shown. The results of this study will help optimize the process of roasting gold-bearing scorodite ore with pyrite concentrate in an atmosphere of superheated water vapor.

Bibliographic link

Gulyashinov P.A., Paleev P.L., Gulyashinov A.N. STUDYING THE PROCESS OF THERMAL DECOMPOSITION OF SCORODITE AND PYRITE // International Journal of Applied and Fundamental Research. – 2017. – No. 12-1. – P. 22-27;URL: https://applied-research.ru/ru/article/view?id=11956 (access date: 09/19/2019). We bring to your attention magazines published by the publishing house "Academy of Natural Sciences"

Few people know that pyrite and iron pyrite are two different names for the same mineral. This stone has another nickname: “dog gold.” Why is the mineral interesting? What physical and magical properties does it have? Our article will talk about this.

Iron pyrite: general physical characteristics

Pyrite (not to be confused with perite) is an opaque mineral with a distinct metallic luster. Other names used are sulfur or iron pyrite. The mineral may contain impurities of copper, gold, selenium, cobalt, nickel and other chemical elements. Does not dissolve in water. Hardness on the Mohs scale: 6-6.5.

Iron pyrite formula: FeS 2. The color of the mineral is straw-yellow or golden. The stone leaves behind a thin greenish-black line. Pyrite crystals are cubic in shape. They are generously covered with shallow straight grooves located parallel to each other. pyrite has the following form.

The word "pyrite" is of Greek origin. It is translated into Russian as “stone that strikes fire.” And this is not just a beautiful metaphor: when struck, pyrite actually sparks. The mineral is distinguished by magnetic and conductive properties; in a humid environment with abundant oxygen, it decomposes.

Distribution in the earth's crust and main deposits of the mineral

Iron pyrite is one of the most common sulfides in the world. The origin of most of its deposits is hydrothermal and sedimentary. Pyrite is formed in the bottom silt of closed seas, during the precipitation of ferrum by hydrogen sulfide. Sometimes it is also present in igneous rocks.

Large deposits of pyrites have been discovered in Russia, Kazakhstan, Spain, Italy, USA, Canada, Norway and Japan. In Russia, deposits of this mineral are found in Altai, the Caucasus, and also within the Voronezh region. It is worth noting that pyrite is very rarely the subject of independent mining. It is usually extracted from the bowels of the earth along the way, during the development of more valuable minerals.

Application of pyrite in industry

“Dog's gold”, or “fool's gold” - this is how pyrite was nicknamed during the Gold Rush. The crystals of the mineral sparkled so seductively that it was often mistaken for a precious metal. By the way, the Spanish conquistadors also got burned by this back in the 16th century. While conquering the New World, they enthusiastically lured “pseudo-gold” from the American Indians.

To be fair, it is worth noting that iron pyrite can indeed be considered gold. The crystal lattice of this mineral often contains particles of noble metal. However, they are usually minor and cannot be extracted. Nevertheless, pyrite deposits very often indicate the presence of gold deposits in a given area.

The main area of application of iron pyrites today is jewelry making. However, it rarely serves as the basis for creating jewelry. Most often, minor inserts for jewelry made from more valuable metals are made from pyrite.

The stone is used as an additive in the production of cement and also for the production of sulfuric acid. Together with crystals of some other minerals, it is also used to create simple detector radio receivers. Due to its ability to produce sparks, pyrite was previously widely used in weapons production.

Iron pyrite in magic

Since ancient times, people have treated this mineral with extreme caution. It was considered a “male” stone. It was believed that pyrite could make a representative of the stronger sex even more decisive, courageous and attractive in the eyes of the ladies.

The ancient Greeks considered pyrite the stone of war and the god Mars. Every soldier took it with him on military campaigns and major battles. Iron pyrite protected the warrior from death and gave him courage in battle. In the dark era of the Middle Ages, alchemists showed considerable interest in the stone.

In modern magic, iron pyrite is used as a protective amulet. However, the mineral must be intact and not chipped, otherwise troubles cannot be avoided. It is generally accepted that pyrite strengthens sleep, improves mood and relieves prolonged depression.

The stone is perfect for Sagittarius and Scorpio. The rest of the zodiac signs should treat him with caution, especially Cancers.

Magnitogorsk State Technical University named after. G.I. Nosova

Current tailings from processing plants are a fine mineral mass consisting of approximately three-quarters ore minerals, the rest being nonmetallic minerals. . The sulfide fraction of the composition predominates in ore minerals: pyrite – 95 – 98%; chalcopyrite – about 1.5%; sphalerite – 2-2.5%. All ore and non-ore minerals of the technological group of current tailings are in their primary form, without signs of oxidation of their surface. Disposal of enrichment tailings has several directions. The most significant direction involves additional extraction of the most valuable components from the tailings, but large-tonnage waste remains unused. The most material-intensive area of application for tailings may be hardening backfill mixtures, which in their structure will be classified as. The properties of such concretes have not been sufficiently studied in the area of the influence of the ore component on the properties of concrete.

Since pyrite is the main component of copper-sulfur ore tailings, its further behavior will affect the properties based on the tailings.

From literary and reference sources, the schemes of chemical reactions of pyrite oxidation are known and generally accepted.

Pyrite oxidation in an acidic environment proceeds according to the overall reaction (1):

The change in the mass and volume of the solid phase when interacting with water at the stoichiometric ratio of the various compounds included in the composition of the binders can be calculated using the method of A.V. Volzhensky.

The absolute volumes of substances participating in the reactions were calculated using the molecular masses and densities of the starting substances of the system.

Basic calculations are presented in table. 1. They show that the absolute volume of the solid phase of the resulting substances increases relative to the absolute volume of the solid phase of the initial reagents. This occurs due to a decrease in the density of the resulting phases as a result of the addition of hydration water or oxidation.

At the same time, a comparison of the absolute volumes of the initial system and the system that arose during interaction with chemical solutions allows us to note another very important point. During a reaction, the absolute total volume of the mixture of starting substances is less than the absolute total volume of the formed substances. Consequently, as a result of reactions with the addition of water and oxidation, contraction (contraction) of the system does not occur.

Calculations show that pyrite oxidation processes are accompanied by a significant increase in the absolute volumes of solid phases. Undoubtedly, this phenomenon initially leads to the filling of pores in the system. Then to an increase in expansion stresses in the hardening system and its subsequent destruction.

The course of pyrite oxidation processes depends on the type and conditions of exposure to reagents. The behavior of pyrite when exposed to various oxidizing agents is shown in Table. 2. The results show that boiling in water leads to the dissolution of the material in an amount of 1% and the same amount of material is fixed in the dry residue after evaporation of the solution, and their sum is almost 100%. Consequently, in boiling water in the absence of oxygen, pyrite oxidation does not occur.

Boiling in a solution of acid and alkali leads to significant oxidation of pyrite. The weight of the initial sample treated with a sulfuric acid solution decreases by 10%, and the dry residue of the filtrate reaches 46% of the weight of the original sample. Boiling in an alkali solution does not reduce the weight of the initial sample, and the dry residue of the filtrate reaches 50%. In this case, the total masses of sediment on the filter (initial sample after boiling) and the dry residue of the filtrate significantly exceed the initial mass, by 36% when exposed to acid and by 51% when exposed to alkali.

This indicates the occurrence of significant oxidative processes under the action of acids and alkalis in the liquid phase on the products of pyrite dissolution. This is confirmed by calculated data on a fivefold increase in the volume of the solid phase during the oxidation of pyrite with alkali (see Table 1).

The above indicates limited areas of application of pyrite tailings, namely, areas that exclude pyrite oxidation. The simultaneous presence of oxygen and water can lead to changes in pyrite according to the scheme discussed above and, consequently, to the destruction of the structure of the material.

Therefore, when designing microconcrete compositions, it is necessary to take into account the increase in the volume of formed substances by regulating the volume of internal pores or create operating conditions that exclude the possibility of pyrite oxidation. Such conditions are provided by mine workings filled with filling mixture. They are the most rational and capacious area for recycling tailings.

Bibliography

- Lowson R. Aqueous oxidation of pyrite by molecular oxygen. - Chem. rev.-1982.- V. 82 - No. 5.- P. 461-497.

- On the influence of some factors on the sorption of potassium butyl xanthate by sulfide minerals / B.M. Koryukin, V.P. Kachalkov, V.A. Yatsenko, M.V. Aksenyushkina // Creation of advanced technologies for processing copper and copper-zinc ores: Coll. scientific tr. - Sverdlovsk: ed. “Unipromed”, 1987. – pp. 97-104.

- Chemical properties of inorganic substances: Textbook. manual for universities / Lidin R.A., Molochko V.A., Andreeva L.L. – M.: Kolos, 2003. – 480 p.

- Volzhensky A.V. Binders. – M.: Higher School, 1986.- 464 p.

See also: